INKAS® Secures Patent for Innovative Self-Protecting Cement

INKAS® Research and Development division is excited to announce its patent for an innovative cement that extends shelf life and significantly reduces greenhouse gases – a global issue caused by one of the most widely used building materials in the world, which has not had a practical solution – until now.

While concrete is the world’s most widely used building material, it is rarely discussed that its use results in hundreds of thousands of tons of cement waste worldwide each year, which is responsible for emitting thousands of tons of CO2 into the atmosphere from producing unnecessary quantities of cement that ultimately end up discarded.

Cement – the main component in concrete – is designed to have a chemical reaction when exposed to water, which triggers it to set and harden into concrete. However, this highly valued feature of cement has a flip side: any exposure to moisture in the surrounding environment triggers the irreversible chemical reaction to begin, resulting in the cement losing its “activity” and rendering it useless.

This inevitable deterioration of cement during its transportation and storage significantly limits its shelf life – which is usually not more than 6 months, and in many cases, less than 3 months from delivery. The cement that expires is essentially unusable and is simply discarded. This creates substantial waste from the natural resources that were spent and the fuel that was burned in order to produce it in the first place.

The only practical solution to date has been to simply store cement carefully. The recommendation is to isolate cement and its dry mixtures from the moisture in their surrounding atmosphere by using airtight multilayer plastic bags, and storing them in dehumidified storage rooms with minimal air circulation, stacked away from the walls.

With regards to cement, it is considered that dividing it into smaller portions and storing it in smaller bags will provide better protection from the surrounding moisture. But the question has remained – what is the ideal size limit of this smaller portion? INKAS® R&D team set out to answer this question, and through thorough research and testing has determined that the ideal size is an individual cement grain.

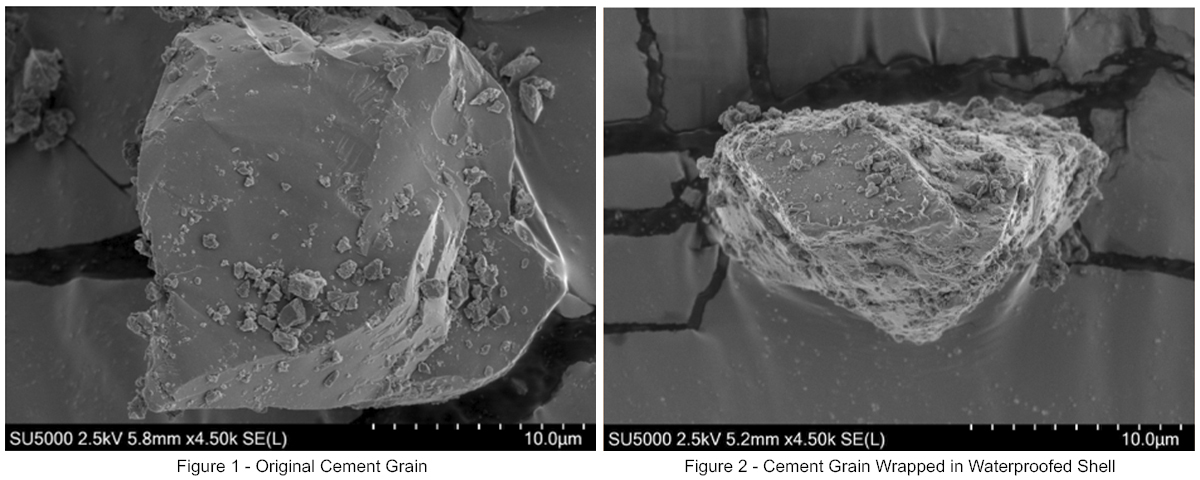

INKAS® R&D team has proven that grains can be individually coated to prevent their reaction with water. To accomplish this, each cement grain is packaged into a waterproof, protective shell. Viewed on the micro-level, these cement grains are coated by a waterproof cover.

INKAS® has developed, produced, tested, and proven this innovative process, and secured a patent for the cement and the process for producing Self-Protected Cement. This process ensures that each cement grain shields itself from moisture in the surrounding environment, which significantly increasing the shelf life of Self-Protected Cement. INKAS® R&D team was able to complete microstructural analysis, statistical analysis of cement aging, and receive the backing needed to validate this process and secure the patent.

To learn more about Self-Protecting Cement, visit the patent page.

Comments are closed.